المنتجات الساخنة

An overview of utilization of slag and sludge from steel

网页2007年3月1日Steel plant slags mainly include blast furnace slag and steel melting slag (open hearth or LD process slag). Various efforts have been made on the utilization of blast furnace and steel slags. These are competitive raw materials for industrial mineral

Contact

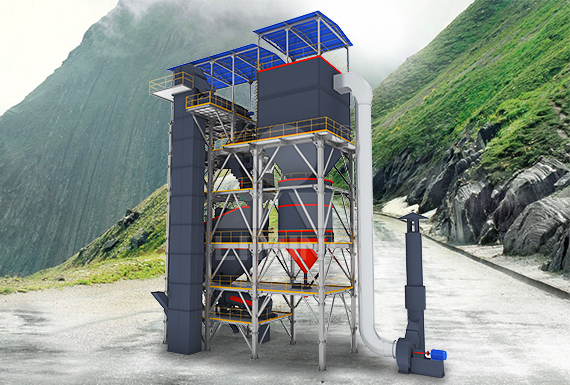

Steel Slag Processing — Ecofertec

网页Ecofertec Slag Processing and Metal Recovery Plant. ECOFERTEC is designing customized steel slag processing and metal recovery plants

Contact

Separation of valuable elements from steel making slag

网页2020年7月1日The blast furnace slag and steelmaking slag generated in the iron and steel making processes in Japan amount to approximately 300 and 120 kg/t-steel,

Contact

Steel Slag an overview ScienceDirect Topics

网页BBOF slag (BOFS) is produced in the steelmaking process by using the molten iron coming from the BF. In the second method, slags are generated in the scrap-based steel

Contact

Treatments and Recycling of Metallurgical Slags

网页2018年11月7日Abstract Steelmaking plants continuously strive to reduce the environmental load in the steelmaking process, resulting in the recycling of energy, water, and other byproducts. In this chapter, techniques for

Contact

Steel Slag Material Description User Guidelines for

网页2016年3月8日Slag processors may handle a variety of materials such as steel slag, ladle slag, pit slag, and used refractory material to recover steel metallics. These materials

Contact

Steelmaking Slag an overview ScienceDirect Topics

网页2012年4月4日Improving process design in steelmaking. D. Sichen, in Fundamentals of Metallurgy, 2005 9.5.1 Slag–metal mixing. In steelmaking, slag–metal mixing is a very

Contact

EAF Slag Treatment for Inert Materials’ Production

网页2015年10月16日Such a project is aimed at transforming EAF slag into a safe and inert by-product, and it has been divided in the following steps: Steel-plant slag microstructural

Contact

Analysis of metallurgical processes and slag utilisation in an

网页@inproceedings{Lundkvist2012AnalysisOM, title={Analysis of metallurgical processes and slag utilisation in an integrated steel plant producing advanced high strength steels},

Contact

Sinter Plant an overview ScienceDirect Topics

网页2010年4月2日The total energy use distribution [24] by various units of the steel plant (coke ovens, sinter plant, blast furnaces, steel shop, rolling mills, and power plant) is shown in Figure 4.2.8. It can be noted that the major share (72%) of energy is required during iron making which includes coke making (12%), iron ore sintering (6%), and blast

Contact

OPERATOR STEEL MELTING EQUIPMENTS DGT

网页Operates and maintain different operation of steel melting shop, staring for m unloading of hot metal,desulphurization process operation and DS slag handling,primary steel making operation. Executes d ifferent flux handling operation, second ary steel making operation (Ladle furnace and RH operation).

Contact

An overview of utilization of slag and sludge from steel industries

网页2007年3月1日LD slags. Great amounts of slags from steel plants are produced through basic oxygen furnace and LD furnace. The main purpose of LD process is to convert the molten pig iron and steel scraps into high quality steel. In India, the generation of steel melting slag is over 2 MT per annum. The amount of steel slags from different steel

Contact

Hydrometallurgical Processes for the Recovery of

网页2020年11月13日Tata Steel discloses in EP 3 333 272 A1 a process f or leach- ing BF (and BOF) residues with a leaching solution of NH 3 and an ammonium salt, (NH 4 ) 2 SO 4,NH 4 Cl, or (NH 4 ) 2 CO 3 ,

Contact

Sulphur removal in ironmaking and oxygen

网页This means that it differs from plant to plant (or even between steel grades) if the sulphur concentration in the metal increases or decreases during the BOF process. Minimum sulphur levels at tapping are reported to be in

Contact

Modeling of the BOF Tapping Process: The Reactions in the Ladle

网页2021年4月8日As shown in Figure 1, BOF carryover slag is added to the bulk slag during the steel tapping.The total amount of the carryover slag is estimated based on the overall mass balance. The total slag carryover is divided into pre-slag, vortex slag and post slag; the relevant proportions of total carryover slag depend on the tapping practice of a steel

Contact

Steel plant slag dumps: A potential source of groundwater

网页2022年2月3日However, the use of slag in India is minimal. Limitations also exist in the use of slag. The high values of P and S are the most common restrictions for internal use of slag in steel plants (Drissen et al. 2009). The use of slag in Bhilai Steel Plant in India was discontinued due to the presence of high S and P contents (Das et al. 2007).

Contact

EAF Slag Treatment for Inert Materials’ Production

网页2015年10月16日DanieliC. in collaboration with Politecnico di Milano, designed an innovative, patent pending, treatment plant to solve some issues associated to metals leaching (i.e., Ba, V, and Cr), and high free lime concentration for carbon steel EAF slag, for the production of artificial aggregates featured by mechanical properties suitable for the

Contact

Products › Ironmaking and steelmaking › Steel Plant

网页Danieli Corus developed the Steel Plant Model to optimize logistics in both existing and new steel plants. The SPM simulates any operational scenario in any steel plant realistically and accurately, in 3D and real time. All

Contact

OBJECTIVE: SCOPE: 3. PROCESS Ministry of Steel

网页vi) Slag Granulation Plant (SGP) / Slag Dumping Yard: During the process of iron making, the impurities are fluxed and removed as slag. The hot liquid slag is made into slag granules by means of high pressure water jets in the Slag Granulation Plant in the Cast House itself (sometimes separate SGP is located at a distance from the furnace proper).

Contact

Co-treatment of Waste From Steelmaking Processes:

网页The iron and steel industry is an energy-intensive sector, and large amounts of waste/ by-products are generated during the steelmaking process, such as CO2, metallurgical slag, and wastewater. Enhancing the development

Contact

Steel Plant an overview ScienceDirect Topics

网页The characteristics of steel plant engineering design are as follows: 1. The steel manufacturing processes have complex characteristics concerning time, space, mass, energy, self-organization, and hetero-organization. Those are reflected as the multiscale, multilevel, multiunit, multifactor, and multiobjective optimization; 2.

Contact

Slag, Iron and Steel JFE MineralAlloy Company,Ltd.

网页We produce blast furnace slags and steelmaking slags at the four integrated steelworks of JFE Steel Corporation and supply them to both the domestic and the overseas markets. We invest in cost reduction strategies and

Contact

Waste Disposal and Recycling in Steel Industry Steel

网页89.6% of solid waste generated from Steel Works is recycled or reused. 17% of the solid waste generated, amounting to approximately 6, 12,300 tonnes in 2008-09 was used to fill low-lying areas and for peripheral road

Contact

The Sintering Process of Iron Ore Fines IspatGuru

网页2013年3月9日Sintering is a thermal process (carried out at 1300 deg C to 1400 deg C) by which a mixture of iron ore, return fines, recycled products of the steel plant industry (such as mill scale, blast furnace dusts, etc.),

Contact

TATA STEEL

网页Tata Steel Kalinganagar is the first Indian plant to be included in the elite Global Lighthouse Network of the World Economic Forum for its leadership in applying Industry 4.0 technologies. India’s first steam ageing facility for ‘accelerated weathering’ of LD slag was commissioned at Tata Steel Jamshedpur.

Contact

Overall Layout Design of Iron and Steel Plants Based on SLP

网页the main plant slag and industrial waste discharge direction, make full use of low-lying land, wasteland, valley and beach land. 3.2 Production Process In the iron and steel plant, supply of raw materials and fuel from raw materials pre-pared workshops to the sinter plant and coking plant workshop,

Contact

Steel Slag an overview ScienceDirect Topics

网页Steel slags. Carlos Thomas, Francisco Agrela, in New Trends in Eco-efficient and Recycled Concrete, 2019. 7.1.2 Types and classification of steel slags. Steel slags (SSs) are usually classified according to the type of furnace in which they are produced. The properties of the slag depend on the type of process used to produce the crude steel,

Contact

Slag Wikipedia

网页Molten slag is carried outside and poured into a dump. Slag is a by-product of smelting (pyrometallurgical) ores and used metals. Broadly, it can be classified as ferrous (by-products of processing iron and steel), ferroalloy

Contact

(PDF) Utilisation of LD slag — An overview

网页2003年4月1日Steel slag can be used as an alternative to remove COD concentration of wastewater adsorption process. Linz-Donawitz (LD) slag can be obtained from steel manufacturing plant.

Contact