المنتجات الساخنة

Thermal analysis and kinetic modeling of pulverized coal

网页2021年4月13日 Pulverized coal injection technique has been widely used as a means of reducing coke consumption during ironmaking process. Owing to the increasing shortage

Contact

Combustion Characteristics of Coal for Pulverized Coal Injection

网页The two types of MDS are mixed with pulverized coal and then injected into the BF under a high gas flow rate in the raceway of the tuyere; this stable combination makes the

Contact

Combustion Characteristics of Coal for Pulverized Coal

网页In the pulverized coal injection (PCI) process of a blast furnace (BF), intensifying the combustion of pulverized coal in the raceway and tuyere is the key to increasing the

Contact

Thermal analysis and kinetic modeling of pulverized coal

网页2021年7月1日 Pulverized coal injection technique has been widely used as a means of reducing coke consumption during ironmakingprocess. Owing to the increasing shortage

Contact

Comparison of semi-coke with traditional pulverized

网页2022年5月6日 potential as an alternative fuel for pulverized coal injection (PCI) and iron ore sintering. X-ray diffraction, Raman spectroscope, and thermal analysis were used to

Contact

Evaluation of Four Coals for Blast Furnace Pulverized

网页2018年8月10日 Abstract: One of the effective methods of reducing coke consumption is pulverized coal injection. The most important problems encountered in this method are

Contact

12.2 Coke Production U.S. Environmental Protection

网页2021年6月25日 iron/steel, increased production of steel by mini-mills (electric arc furnaces that do not use coke), and the lowering of the coke:iron ratio used in the blast furnace (e.

Contact

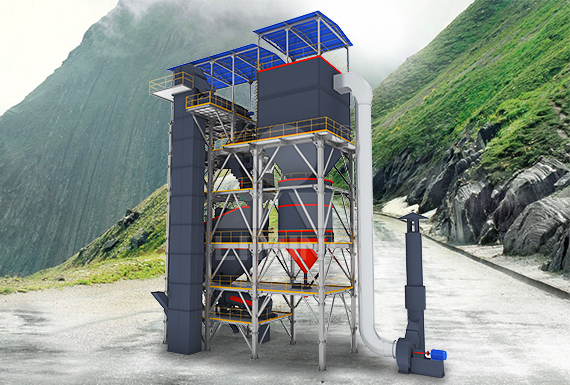

Pulverized Coal Injection (PCI) System for Blast

网页This is a facility aiming at the life-prolonging measure against production cost reduction and a coke oven by direct injection of cheap coal into a blast furnace instead of expensive coke, and abundant injection of high PCI

Contact

FundamentalStudy Combustionof Pulverized Coal into

网页Pulverized coal has been injected into blast furnace tuyeres from various points of view, suchas to encounter coke supply shortage, to reduce hot metal cost with increased use

Contact

Evaluation of combustion behaviour of coal blends for use in pulverized

网页2014年12月5日 Co-injection of non coking coal and natural gas in blast furnace. ISIJ Int., 39 (1999), pp. 229-238. Evaluation of petrology and reactivity of coal blends for use in pulverized coal injection (PCI) Int. J. Coal Geology, 68 (1) (2006), pp. 14-29. Article. Download PDF View Record in Scopus Google Scholar

Contact

FundamentalStudy Combustionof Pulverized Coal into

网页Pulverized coal has been injected into blast furnace tuyeres from various points of view, suchas to encounter coke supply shortage, to reduce hot metal cost with increased use of non-coking coal and to increase the productivity. However, recently, an intensified pulverized coal injection (PCI) has been performed in Europel'2) and will be

Contact

12.2 Coke Production U.S. Environmental Protection

网页2021年6月25日 mixing bins where the various types of coal are stored. The coal is transferred from the mixing bins to the coal crusher where it is pulverized to a preselected size between 0.15 and 3.2 mm (0.006 and 0.13 in.). The desired size depends on the response of the coal to coking reactions and the ultimate coke strength that is required.

Contact

(PDF) Efficient way to use of non-coking coals in

网页2014年6月26日 The implementation of the technique has yielded use of up to 25% pulverized coal injection, 20% raw petroleum coke as a component of coal blend. Results show that the coal blend having composite

Contact

Efficient way to use of non-coking coals in non-recovery

网页2014年6月26日 The implementation of the technique has yielded use of up to 25% pulverized coal injection, 20% raw petroleum coke as a component of coal blend. Results show that the coal blend having composite coking potential value of 4.8 is desired to achieve the targeted coke strength after reaction of 65.

Contact

Combustion Characteristics of Coal for Pulverized Coal Injection

网页Pulverized coal injection (PCI) is employed in blast furnace tuyeres attempting to maximize the injection rate without increasing the amt. of unburned char inside the stack of the blast furnace. When coal is injected with air through the injection lance, the resolidified char will burn in an atm. with a progressively lower oxygen content and

Contact

Use of PCI in blast furnaces ICSC

网页2018年2月2日 One way to achieve this is through the injection of pulverised coal directly into the BF. Pulverised coal injection (PCI) provides important economic and operational benefits. These include: lower consumption of expensive coking coals. Replacing coke with cheaper soft coking or thermal coals reduces reductant costs. It takes about 1.4 t of

Contact

Evaluation of four coals for blast furnace pulverized coal injection

网页2010年3月1日 One of the effective methods of reducing coke consumption is pulverized coal injection. The most important problems encountered in this method are reduced permeability, unburned and high ash content. To select the best coal for injection, suitable tests can be used. Therefore, experiments such as proximate and ultimate analysis,

Contact

(PDF) Impact of PCI Coal Quality on Blast Furnace

网页2003年1月1日 Philip Bennett. Pulverized coal injection has assisted the steel industry to lower operating costs, extend coke oven life and lower greenhouse emissions. As the understanding of the impact of

Contact

Comparison of semi-coke with traditional pulverized coal injection

网页2022年1月11日 Processes of coking, iron ore agglomeration and ironmaking in blast furnace (BF) constitute over 75% of the energy consumption in all processes of iron and steel production, and fuel consumption is the primary candidate of energy consumption [].Pulverized coal injection (PCI) technology is an important method to save expensive

Contact

Coal 2021 Analysis IEA International Energy Agency

网页Coal 2021 is the world’s most comprehensive forecast of coal demand, supply and trade, based on detailed analysis of the most recent data at country and sectoral level, broken down by coal grade (thermal coal, coking coal, pulverised coal injection and lignite).Coal 2021 presents real data for 2019 and 2020, the most up-to-date estimates for 2021, and

Contact

Efficient way to use of non-coking coals in non-recovery

网页2014年6月26日 The implementation of the technique has yielded use of up to 25% pulverized coal injection, 20% raw petroleum coke as a component of coal blend. Results show that the coal blend having composite coking potential value of \hbox{$\geqslant $} ⩾ 4.8 is desired to achieve the targeted coke strength after reaction of \hbox{$\geqslant $}

Contact

Understanding Pulverized Coal Injection in Blast

网页2018年10月21日 Pulverized coal injection (PCI) is a well-established technology for hot metal (HM) production in a blast furnace (BF). It is practiced in most of the BFs and all the new BFs are normally built with

Contact

Pulverized Coal Injection???!!! LinkedIn

网页2015年10月2日 With 170 200 kg/t-HM pulverized coal injection, coke consumptions as low as 286 320 kg/t-HM has been achieved in modern blast furnaces. However, global average for PCI remained at 125 kg/t-HM

Contact

Coking Coal an overview ScienceDirect Topics

网页Table 11.8 provides data on coking coal washeries in India in the year 2019–20. It may be seen that the total capacity of the coking coal washeries was 29.84 MTA (Million Tonne Annum).The share of public sector was 21.98 MTA and private sector 7.86 MTA. Table 11.9 shows performance of coking coal washeries for last 10 years. Fig. 11.5 provides details

Contact

Innovations in Coke Production, Market Trends: Insights

网页2019年10月23日 1. RINL (Vizag Steel) expects to produce 7.5 million t of steel in 2019, with the use of 4.7 million t of high-coking coal; in 2022, pulverized-coal consumption of 1.35 million t is expected. 2. The National Mineral Development Corporation (NMDC) expects to introduce a new plant with capacity of 3 million t/yr in 2019. 3.2 South East Asia

Contact

Evaluation of Four Coals for Blast Furnace Pulverized

网页2018年8月10日 Issue 3 Evaluation of Four Coals for Blast Furnace Pulverized Coal Injection • 9 • at temperatures of 110 and 870 'c, respectively. Ac cording to the ASTM-D3174, 1 g of dried coal was heated at 850'C under air during 2 h. Remained mass of the burnt coal indicated the ash content of the coal. The fixed carbon percentage was

Contact

Modelling in-furnace phenomena of pulverized coal injection

网页2012年6月1日 A number of minerals, such as iron ore, coking coal and pulverized coal, are involved in this process. Pulverized coal injection (PCI) technology is widely used in this process (Shen et al., 2008a) for economical, operational and environmental benefits. In this operation, pulverized coal is injected with gas into the blast furnace via a

Contact

Pulverized Coal Injection in a Blast Furnace

网页2013年5月10日 Pulverized coal injection (PCI) is a process which involves injecting large volumes of fine coal particles into the raceway of the blast furnace (BF). Pulverized coal is an important auxiliary fuel used in the BF

Contact

Metallurgical Coal Market Report Global Forecast To 2028

网页Report Details. Table of Content. Free Sample. The global metallurgical coal market is expected to grow at a CAGR of 3.5% during the forecast period, from 2021 to 2030. The growth in this market is attributed to the increasing demand for metallurgical coal in various applications such as power generation and steel production.

Contact